Добро пожаловать Shandong Yijin Cnc Machine Tool Co., Ltd. Веб - сайт

В современном мире промышленность сталкивается с беспрецедентными вызовами: рост конкуренции, требования к качеству продукции, необходимость снижения затрат и повышения экологической устойчивости. В этом контексте высокоточные системы контроля emerge как ключевой фактор трансформации, предлагая инновационные решения для оптимизации процессов, минимизации ошибок и обеспечения беспрецедентной точности. Эта статья углубляется в то, как эти системы формируют будущее промышленности, предоставляя всесторонний обзор их преимуществ, технологий и практических применений.

Высокоточные системы контроля refer to advanced technological setups designed to monitor, measure, and manage industrial processes with extreme accuracy. They integrate sensors, software, and hardware to ensure that operations adhere to predefined standards, reducing variability and enhancing reliability. From manufacturing and logistics to energy and healthcare, these systems are becoming indispensable for achieving operational excellence.

The core components include precision sensors that detect minute changes, data acquisition units that collect information in real-time, and analytical software that interprets data to make informed decisions. For instance, in automotive manufacturing, high-precision control systems can detect deviations in assembly lines as small as micrometers, preventing defects before they escalate.

Why are they crucial? In an era where margins are thin and customer expectations are high, even minor errors can lead to significant losses. High-precision control mitigates risks by providing continuous oversight, enabling proactive adjustments rather than reactive fixes. This not only saves costs but also boosts overall productivity.

Industrial control has come a long way from manual inspections and basic mechanical systems. In the early 20th century, processes were largely hands-on, with workers relying on experience and rudimentary tools. The advent of automation in the mid-1900s introduced programmable logic controllers (PLCs), which allowed for more consistent operations but still lacked the precision needed for today's demands.

The digital revolution of the late 20th and early 21st centuries brought about a paradigm shift. With the integration of computers and networks, control systems became smarter and more interconnected. The rise of the Internet of Things (IoT) and Industry 4.0 has further accelerated this evolution, enabling systems that are not only precise but also adaptive and predictive.

Today, high-precision control systems leverage artificial intelligence (AI) and machine learning to learn from data, anticipate issues, and optimize processes autonomously. For example, in semiconductor manufacturing, where tolerances are incredibly tight, AI-driven systems can predict equipment failures and schedule maintenance, reducing downtime by up to 30%.

This historical progression highlights how precision control has transitioned from a luxury to a necessity, driven by technological advancements and increasing industrial complexity.

Several cutting-edge technologies form the backbone of high-precision control systems. Understanding these is essential to appreciate their impact.

Датчики и измерительные приборы: Advanced sensors, such as laser scanners, capacitive sensors, and vision systems, provide accurate data on parameters like temperature, pressure, and dimensions. For instance, in pharmaceutical production, optical sensors ensure that pill coatings are uniform, critical for efficacy and safety.

Программное обеспечение для анализа данных: Software platforms like SCADA (Supervisory Control and Data Acquisition) and MES (Manufacturing Execution Systems) process vast amounts of data in real-time. They use algorithms to identify patterns, anomalies, and trends, facilitating informed decision-making. In energy sectors, such software helps optimize grid performance, reducing waste and improving reliability.

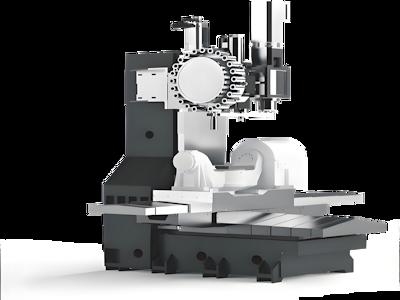

Робототехника и автоматизация: Robots equipped with high-precision actuators perform tasks with minimal error. In electronics assembly, robotic arms place components on circuit boards with accuracy down to micrometers, significantly enhancing production speed and quality.

Интернет вещей (IoT): IoT devices connect physical assets to digital networks, enabling seamless data flow and remote monitoring. In agriculture, IoT-based control systems monitor soil moisture and nutrient levels, allowing for precise irrigation and fertilization, which boosts yields while conserving resources.

Искусственный интеллект и машинное обучение: AI algorithms analyze historical and real-time data to predict outcomes and recommend actions. In predictive maintenance, AI can forecast when machinery will fail, scheduling repairs before breakdowns occur, thus avoiding costly disruptions.

These technologies synergize to create systems that are not only precise but also intelligent and scalable, adaptable to various industrial contexts.

The adoption of high-precision control systems offers myriad benefits that translate directly to competitive advantage and sustainability.

Повышение качества продукции: By minimizing variations, these systems ensure that products meet strict specifications consistently. In the food industry, for example, precision control in packaging prevents contamination and ensures accurate labeling, enhancing consumer trust and compliance with regulations.

Увеличение эффективности производства: Automated control reduces manual intervention, speeding up processes and lowering labor costs. Studies show that industries implementing high-precision systems can achieve efficiency gains of 20-40%, as seen in automotive manufacturing where assembly lines operate 24/7 with minimal supervision.

Снижение отходов и затрат: Precision minimizes material waste by optimizing usage. In textile manufacturing, control systems cut fabrics with exact measurements, reducing scrap by up to 15%, which not only saves money but also supports environmental goals.

Улучшение безопасности: These systems monitor hazardous environments, alerting operators to potential dangers. In chemical plants, sensors detect leaks early, preventing accidents and protecting workers.

Гибкость и адаптивность: Modern systems can be reconfigured quickly to handle different products or processes, making industries more responsive to market changes. This is particularly valuable in custom manufacturing, where batch sizes are small and requirements vary.

Overall, the ROI from high-precision control is substantial, often paying for itself within a few years through savings and increased revenue.

High-precision control systems are versatile, finding applications across diverse sectors. Here are some illustrative examples.

Автомобильная промышленность: In car manufacturing, systems control robotic welding, painting, and assembly with micron-level accuracy. This ensures that vehicles are built to exact standards, reducing recalls and enhancing brand reputation. Companies like Tesla use such systems to achieve high production rates while maintaining quality.

Аэрокосмическая отрасль: Precision is paramount here, where components must withstand extreme conditions. Control systems monitor machining of turbine blades and assembly of aircraft, ensuring compliance with rigorous safety standards. For instance, Boeing employs advanced metrology systems to verify part dimensions during production.

Фармацевтика: In drug manufacturing, control systems oversee mixing, tablet pressing, and packaging to ensure dosage accuracy and sterility. This is critical for patient safety and regulatory approval. Systems like those from Siemens help pharmaceutical companies maintain GMP (Good Manufacturing Practices) compliance.

Энергетика: In power plants, control systems optimize fuel consumption and emissions. Smart grids use precision monitoring to balance supply and demand, integrating renewable sources efficiently. This reduces carbon footprints and operational costs.

Сельское хозяйство: Precision agriculture uses control systems for planting, irrigation, and harvesting. Drones and sensors collect data on crop health, enabling targeted interventions that maximize yield and minimize resource use.

These examples demonstrate how high-precision control is transforming industries by making processes smarter, safer, and more sustainable.

Despite their benefits, implementing high-precision control systems comes with challenges. Addressing these is key to successful adoption.

Высокие первоначальные инвестиции: The cost of advanced sensors, software, and integration can be prohibitive for small businesses. Solutions include phased implementation, leasing options, and seeking government grants or subsidies aimed at promoting industrial innovation.

Сложность интеграции: Retrofitting old systems with new technology can be technically challenging. Partnering with experienced vendors and using modular approaches can ease this transition. Training programs for staff are also essential to build internal expertise.

Проблемы с данными и кибербезопасностью: With increased connectivity, systems are vulnerable to cyber threats. Implementing robust security protocols, such as encryption and access controls, mitigates risks. Regular audits and updates ensure ongoing protection.

Сопротивление изменениям: Employees may be hesitant to adopt new technologies. Change management strategies, including clear communication of benefits and involving workers in the process, foster acceptance and smooth implementation.

By proactively addressing these challenges, industries can harness the full potential of high-precision control systems without significant disruptions.

The future of high-precision control is bright, with several emerging trends set to redefine industrial landscapes.

Интеграция с искусственным интеллектом: AI will become even more pervasive, enabling systems that self-optimize in real-time. For example, in smart factories, AI could dynamically adjust production parameters based on demand fluctuations and resource availability.

Расширенная реальность (AR/VR): AR and VR technologies will enhance monitoring and maintenance. Technicians could use AR glasses to overlay diagnostic data onto physical equipment, speeding up repairs and reducing errors.

5G и edge computing: The rollout of 5G networks will support faster data transmission, while edge computing will process data closer to the source, reducing latency. This is crucial for applications requiring instant responses, such as autonomous robotics.

Устойчивое развитие: Precision control will play a pivotal role in achieving circular economy goals by optimizing resource use and reducing waste. Innovations in biodegradable materials and energy-efficient processes will be driven by these systems.

Персонализация массового производства: As consumer demand for customized products grows, control systems will enable mass customization without sacrificing efficiency. This trend is already visible in industries like apparel and electronics.

These advancements promise to make high-precision control even more integral to industrial success, fostering innovation and resilience.

In conclusion, high-precision control systems are not merely a technological upgrade but a strategic imperative for the future of industry. They empower businesses to achieve unparalleled levels of quality, efficiency, and sustainability, positioning them for long-term success in a competitive global market. By investing in these systems, industries can navigate challenges, seize opportunities, and lead the way toward a smarter, more precise industrial era.

As we look ahead, the convergence of AI, IoT, and other technologies will continue to enhance these systems, making them more accessible and effective. Now is the time for forward-thinking companies to embrace high-precision control and secure their place at the forefront of industrial innovation.

For those ready to take the leap, numerous resources and experts are available to guide implementation. Start by assessing your current processes, identifying areas for improvement, and exploring partnerships with technology providers. The future is precise—make sure your industry is part of it.