Добро пожаловать Shandong Yijin Cnc Machine Tool Co., Ltd. Веб - сайт

В современном мире промышленности конкуренция становится все более жесткой. Чтобы оставаться на плаву и процветать, предприятия должны постоянно искать способы оптимизировать свои процессы, снижать затраты и повышать производительность. Одним из ключевых инструментов для достижения этих целей является автоматический пресс. Это оборудование не только ускоряет производственные линии, но и обеспечивает высокую точность, безопасность и надежность. В этой статье мы глубоко погрузимся в тему автоматических прессов, рассмотрим их типы, преимущества, примеры успешного внедрения и дадим практические советы по выбору. Если вы ищете способ революционизировать ваше производство, читайте дальше — эта информация может изменить все!

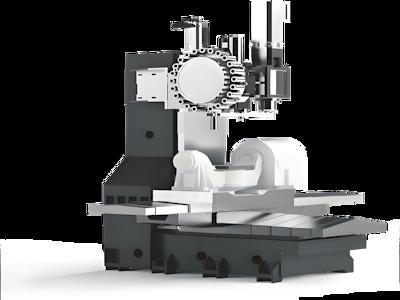

Автоматический пресс — это машина, которая использует механическое или гидравлическое усилие для формования, штамповки или сжатия материалов, таких как металл, пластик или резина, с минимальным вмешательством человека. В отличие от ручных прессов, которые требуют постоянного оператора, автоматические версии оснащены системами управления, которые позволяют программировать операции, обеспечивая повторяемость и высокую скорость. Важность автоматических прессов в производстве невозможно переоценить. Они сокращают время цикла, уменьшают человеческие ошибки и повышают общую эффективность. Например, на автомобильном заводе автоматический пресс может производить тысячи деталей в час с точностью до микрона, что было бы невозможно при ручной работе. Это не просто машина — это инвестиция в будущее вашего бизнеса.

Существует несколько типов автоматических прессов, каждый из которых предназначен для specific applications. Гидравлические прессы используют жидкость под высоким давлением для создания усилия и идеальны для heavy-duty tasks, such as forging or molding large metal parts. Они предлагают высокую мощность и плавность хода, но могут быть более дорогими в обслуживании. Механические прессы, с другой стороны, используют mechanical linkages and are faster for high-volume production, such as in the packaging industry. Пневматические прессы rely on compressed air and are suitable for lighter tasks, like assembling small components. Additionally, there are servo-driven presses that provide precise control and energy efficiency. Choosing the right type depends on your material, production volume, and budget. For instance, if you're in the aerospace industry, a hydraulic press might be best for its strength, while a mechanical press could suffice for mass-producing consumer goods.

Внедрение автоматического пресса приносит multitude of benefits. First and foremost, it significantly increases labor efficiency. By automating repetitive tasks, workers can focus on more complex activities, reducing fatigue and the risk of injuries. Studies show that automation can boost productivity by up to 30% in manufacturing settings. Secondly, automatic presses enhance product quality through consistency. Human variability is eliminated, ensuring that every part meets exact specifications. This reduces waste and rework, saving money in the long run. Thirdly, safety is improved as machines handle hazardous operations, minimizing accidents. Moreover, automatic presses often come with IoT capabilities, allowing for real-time monitoring and predictive maintenance, which further reduces downtime. From a financial perspective, the initial investment is quickly recouped through lower labor costs and higher output. For example, a company that switched to automatic presses reported a 20% reduction in operational costs within the first year.

To illustrate the impact, let's look at some real-world examples. In the automotive sector, a major manufacturer integrated automatic hydraulic presses into their assembly line. This move reduced production time per vehicle by 15% and decreased defect rates by 25%. The presses were programmed to handle multiple tasks, from pressing bearings to forming body panels, showcasing their versatility. In the food industry, a packaging company adopted pneumatic automatic presses for sealing containers. This not only sped up the process but also ensured hermetic seals, extending shelf life and reducing spoilage. Another case is in electronics, where servo presses are used for delicate assembly work, such as inserting components into circuit boards. The precision achieved prevented damage to sensitive parts, leading to higher yield rates. These examples demonstrate that regardless of the industry, automatic presses can be tailored to deliver tangible results.

Selecting the right automatic press requires careful consideration. Start by assessing your production needs: What materials will you be working with? What is your expected output volume? For high-volume operations, a mechanical press might be ideal due to its speed. If precision is key, opt for a servo-driven model. Next, evaluate the available space in your facility; some presses are compact, while others require significant floor area. Budget is another critical factor—while automatic presses have a higher upfront cost, consider the total cost of ownership, including maintenance and energy consumption. It's also wise to choose a press from a reputable manufacturer that offers good warranty and support. Demo sessions can help you test the equipment before purchase. Additionally, think about future scalability; a modular press might allow for upgrades as your business grows. Don't forget training for your staff to ensure smooth operation and maximize the benefits.

В заключение, автоматические прессы represent a transformative technology for modern production. They not only enhance efficiency and quality but also pave the way for smarter, more sustainable manufacturing. As Industry 4.0 continues to evolve, integrating such equipment will become essential for staying competitive. Whether you're a small workshop or a large factory, investing in an automatic press can lead to significant gains. Remember, the goal is not just to automate but to optimize—every press should align with your specific goals. We hope this article has provided valuable insights. If you're ready to take the next step, consult with experts and start your journey towards a more efficient production line. The future is automated, and it's time to embrace it!